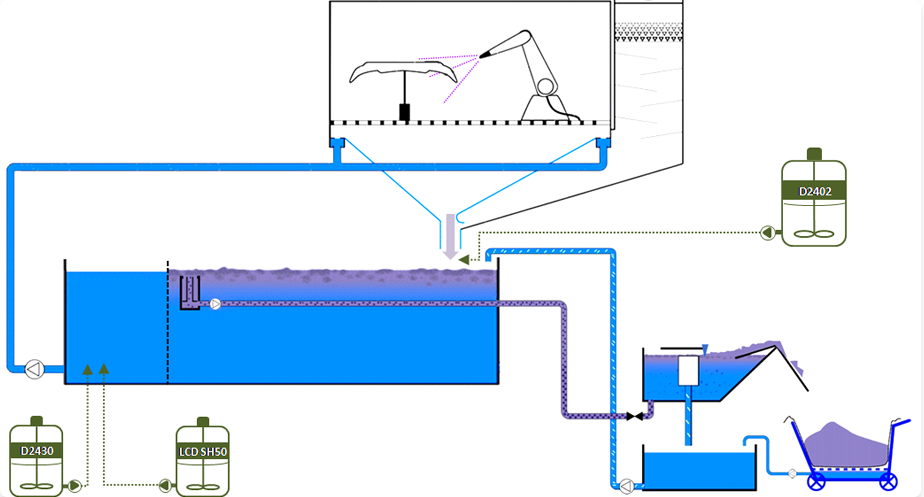

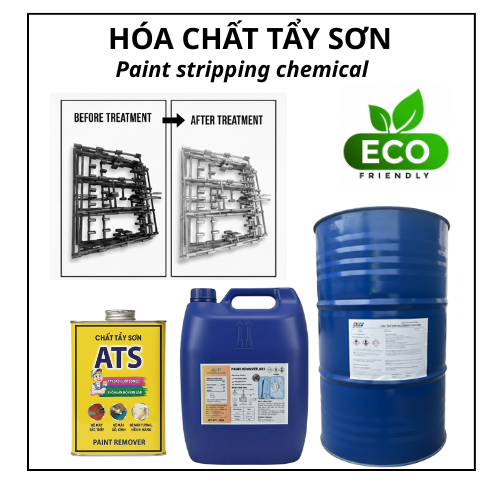

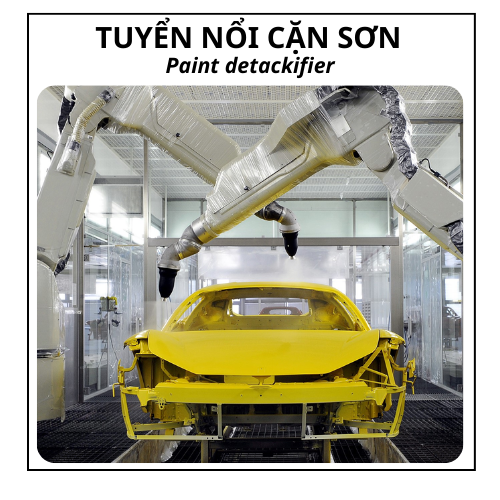

In the process of painting the surface of the product on the paint lines, there is a part of paint material that does not cling to details but goes out into the air, affects the operation of the line and causes a variety of environmental problems. school work. Facing that situation, we have developed the Paint detackification technology to remove this amount of paint effectively.

The focus of Paint detackification technology is the Paint detackifier chemical kit including the following main products:

– Detackifier D2430: Eliminate the adhesion of paint.

– LCD SH50: Initializing operating environment for D2430.

– Flocculant D2402: Agglomeration of suspended solids and flotation from water.

– HB smell control: Control bacteria and deodorize the system.

Paint detackificati technology helps reduce line maintenance costs and ensures a working environment for employees. The Paint detackifier kit is optimally designed to handle all systems of polyester, polyurethane, acrylic, epoxy, alkyd, … with outstanding advantages:

– Simple operation.

– Ensuring the quality of circulating water.

– Paint residue is porous, easy to remove from water.

– Minimize system corrosion problems.

– Reduce cost and frequency of system maintenance.

Control odor and bacteria, improve working environment.

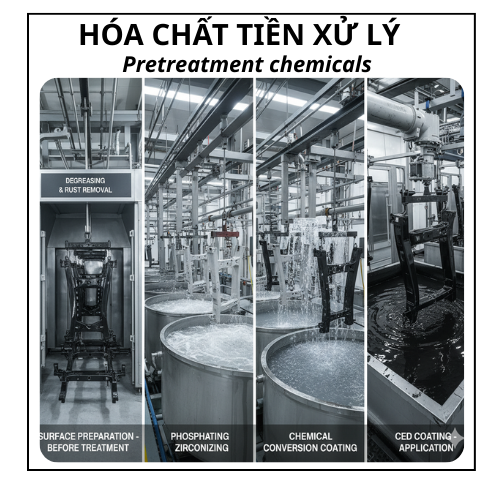

TECHNOLOGY CHART AND REAL PICTURES OF PRODUCT USE