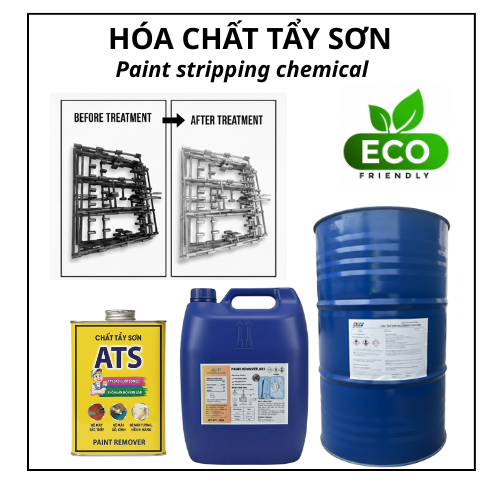

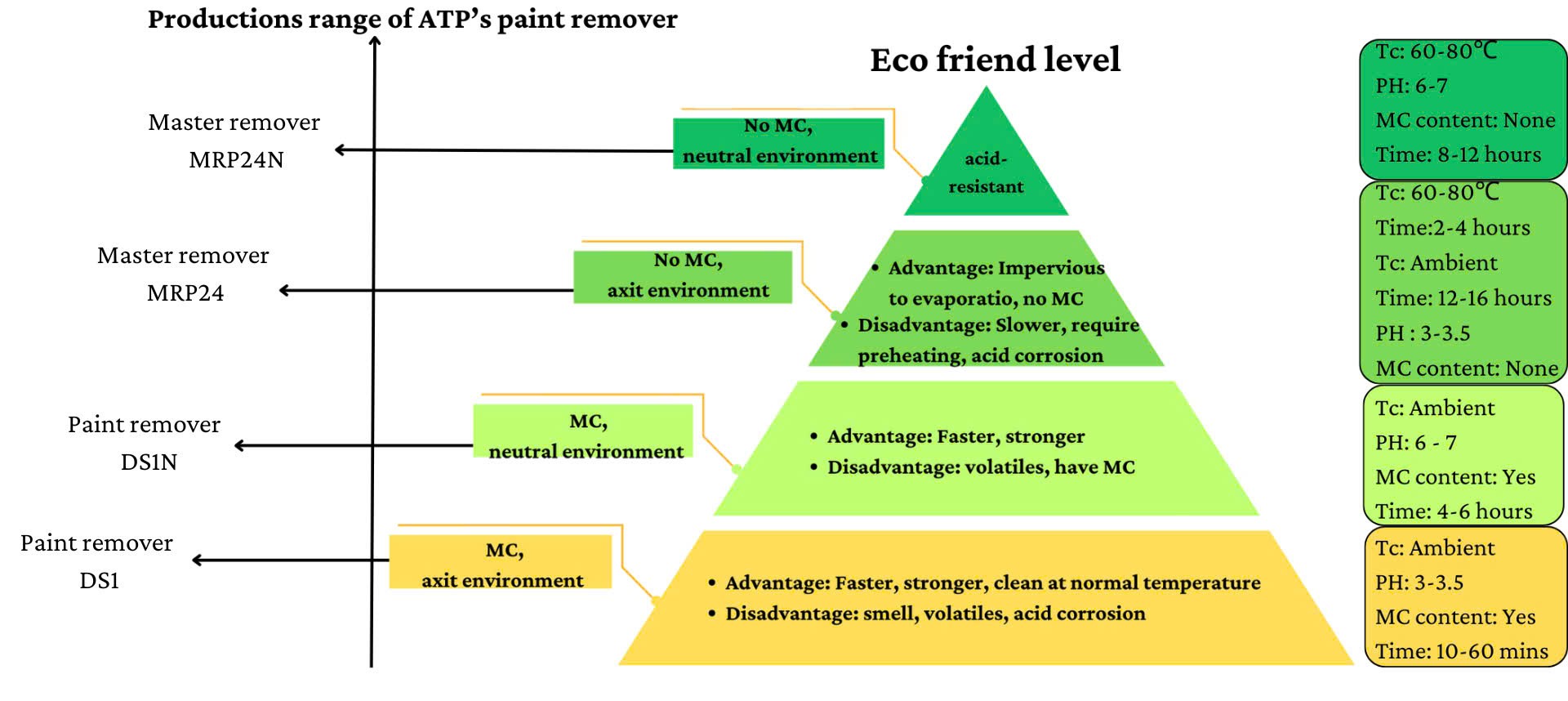

I. INTRODUCTION TO PAINT REMOVAL TECHNOLOGY – REMOVER PAINT _ DS1

Remover Paint _ DS1 is a specialized technology that allows chemicals to quickly penetrate and remove coating layers from metal surfaces such as steel, iron, cast iron, aluminum, zinc, and stainless steel.

It breaks the adhesion bond between the metal surface and the paint layer, providing a clean surface rapidly and improving the efficiency of painting lines.

Remover Paint _ DS1 can remove most types of paint on metal surfaces, including oil-based paint, water-based paint, powder coating, urethane paint, and epoxy paint.

It is widely applied across various industrial sectors.

Key Advantages of Remover Paint _ DS1:

Fast stripping speed

Increased stripping capacity

Cost optimization

Compatible with multiple coating technologies: wet paint, powder coating, electrostatic paint, and electrophoretic coating (ED coating)

II. GENERAL CHARACTERISTICS

-

Appearance: Slightly cloudy liquid.

-

Solubility: Poorly soluble in water; easily volatile.

Storage temperature: Store at room temperature (16–32°C); avoid direct sunlight, heat sources, sparks, and metal contact.

III. EQUIPMENT

To minimize chemical loss due to evaporation, the stripping tank should be equipped with a lid that can be tightly closed.

The pump inlet should be positioned at least 30 cm (12 inches) above the bottom of the stripping tank to reduce foam formation.

Paint stripping is a process that is easily contaminated with solid residues; therefore, the filtration system should remove solid paint particles to extend the solution’s lifespan.

Manual removal using a skimming net can also be applied.

IV. INSTRUCTIONS FOR USE

-

Prepare the soaking tank with a sealed lid.

-

Add Remover Paint _ DS1 into the tank.

Note: Use the chemical in its original concentration. Do not dilute. -

Immerse the basket containing the jigs that require paint removal into the soaking tank.The stripping time depends on several factors including operating conditions, paint type, paint thickness, and the shape/structure of the workpie

-

After completing the stripping process, lift the workpiece and allow time for the solution adhering to the surface to drain back into the tank.

To minimize chemical loss carried out on the workpiece, spray with mist water directly over the tank. -

Rinsing:Rinse the workpiece in a clean water tank with air agitation and overflow.

Alternative rinsing method:

Rinse with clean water using an automatic spray system or manual spraying over an empty tank.

This method helps reduce the amount of rinse water required for wastewater treatment. Note: Use the rinse water to replenish the evaporation loss in the stripping tank.

V. PRECAUTIONS AND STORAGE

-

Do not come into direct contact with the solution.

-

Wear appropriate protective equipment during handling (goggles, rubber gloves, mask, protective clothing, etc.).

-

Use in a well-ventilated area or ensure proper exhaust ventilation.

-

Treat wastewater in accordance with current environmental regulations.